In the previous blogs, I gave you a brief introduction about Ultrasonic and Radiographic testing. Both of these methods are volumetric Inspection methods and are used to carry out to inspection of the test piece throughout its Volume. But these methods have sensitivity limitations and are not suggested for Detection of Fine Cracks on the surface or slightly subsurface of Materials. moreover, sometimes the detection of surface discontinuities is of more importance. This is when Magnetic particle Testing and Dye Penetrant Testing becomes Important NDT methods.

In this article, I will give you a brief introduction to Magnetic Particle Testing.

Introduction:

Magnetic particle testing is used to detect surface and shallow subsurface discontinuities in ferromagnetic materials (no other type of material) such as iron, nickel, cobalt, and some of their alloys.

This method includes magnetizing the part using direct/indirect method by applying a magnetic field into the part and detecting the flaws by application of fine metallic particles.

Magnetic particle testing is capable of revealing surface discontinuities including those that are too small or too tight to be seen by the unaided eye.

These principles were even used in the way back 1968 and with continuous research and development, it has now become a reliable NDT test method to detect surface and slightly subsurface discontinuities.

To know more about how Magnetic particle began, read our blog History Of NDT.

Basic Principle :

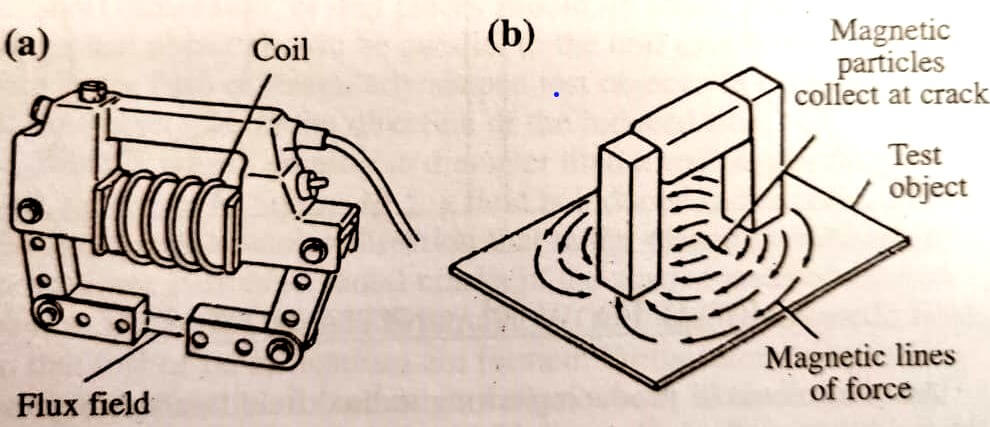

Magnetic particle testing is based on the phenomenon called magnetic flux leakage occurring in a ferromagnetic test object in the presence of a discontinuity.

In the above figure: magnetic field lines are direction flowing from the South pole to north pole. Now when these magnetic field lines come across a discontinuity the magnetic field lines travel through the air across the discontinuity causing generation of poles around the discontinuity periphery. Now when fine magnetic particles spread around this Magnetic flux leakage area, the particles get accumulated around the flux leakage area making the discontinuity easily visible.

What are the magnetic field and magnetic field lines?

A magnetic field exists within and around a permanent magnet or within and around an electric current-carrying conductor.

A magnetic field line or magnetic flux line shows the direction of a magnet‘s force and the strength of a magnet.

Characteristics of magnetic Field Lines:

- they do not intersect each other

- the relative strength of magnetic field lines is given by the degree of closeness (they are strongest and most dense at poles)

- their direction is indicated by arrows in the line at any point

- the direction of field line inside the magnet is from south to north pole and vice-versa outside the magnet

- They seek the path of least resistance between opposite magnetic poles.

- They never cross one another.

- Magnetic lines of force only enter or leave from the poles of the magnet.

Quick Fact: A circular magnet with no irregularities has no poles.

The principle behind the Magnetization of test item:

Principally when current passes through a conductor, a magnetic field is formed in and around the conductor this is called induced magnetic field and vice versa also occurs.

To know More about Induced Magnetic fields https://en.wikipedia.org/wiki/Faraday%27s_law_of_induction

If the conductor has a uniform shape like a circular rod. The density of the external field is uniform at the same radial point along the length of the conductor.

At any point on the conductor, the magnetic field is the strongest at the surface of the conductor and decreases as the distance increases from the conductor surface.

In what direction the Magnetic field will be induced?

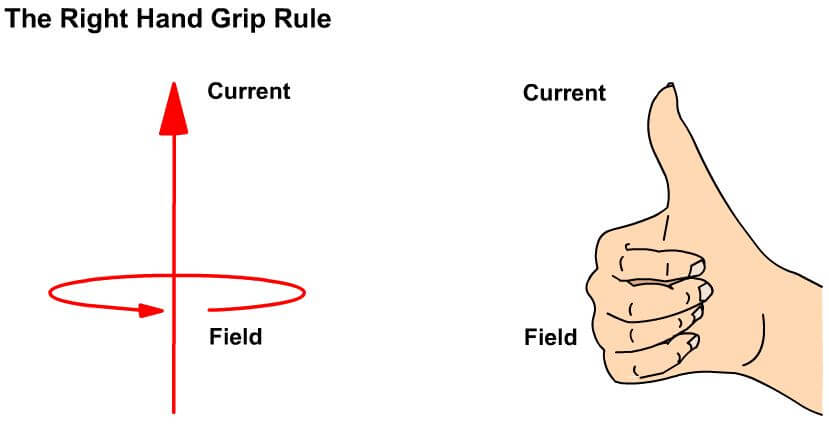

The direction of the magnetic field is at a 90◦ angle to that of the current in the conductor.

The right-hand thumb rule is an easy method for determining the direction of an electrically induced magnetic field.

As shown in the above image if we grasp the conductor in our right hand with thumbs pointing in the direction of the flow of current. The figures will be pointing in the direction of the magnetic field line and vice versa also happens.

This phenomenon is used for different types of magnetization of the test piece while performing magnetic particle testing.

Types of magnetization:

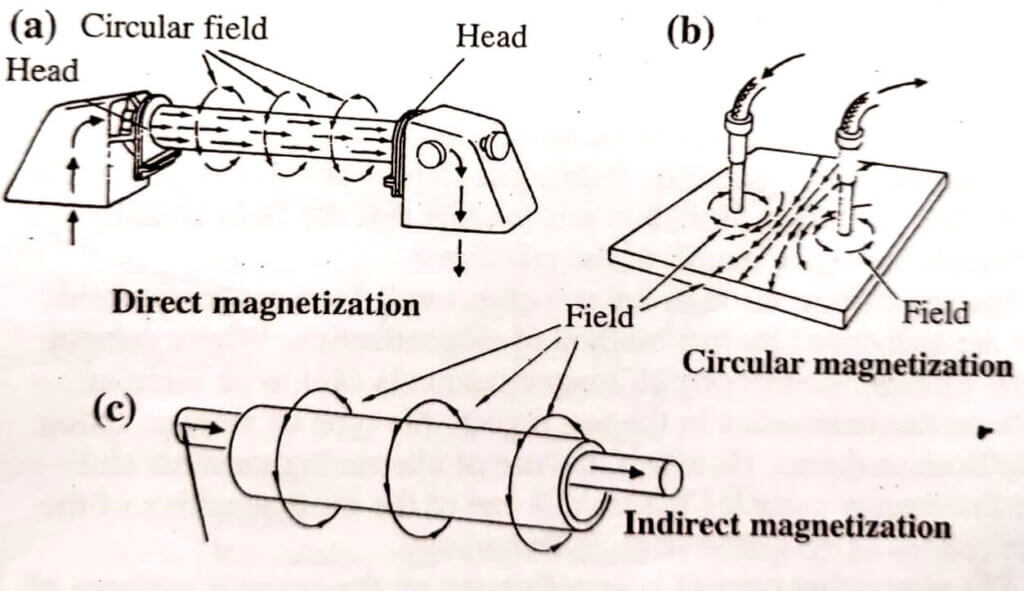

Circular magnetization: a circular magnetic can be induced in a test object either by Direct magnetization or Indirect magnetization.

Direct Magnetization: Involves the passing of magnetizing current directly through the test object using headshot or prods.

Indirect Magnetization: Involves passing the current through a conductor surrounded by the test Object.

As shown in the above figure in (a) and (b) Current is passed directly in the test Piece causing direct magnetization of the test piece and in (c) the current is passing through a coil causing indirect magnetization of the test item.

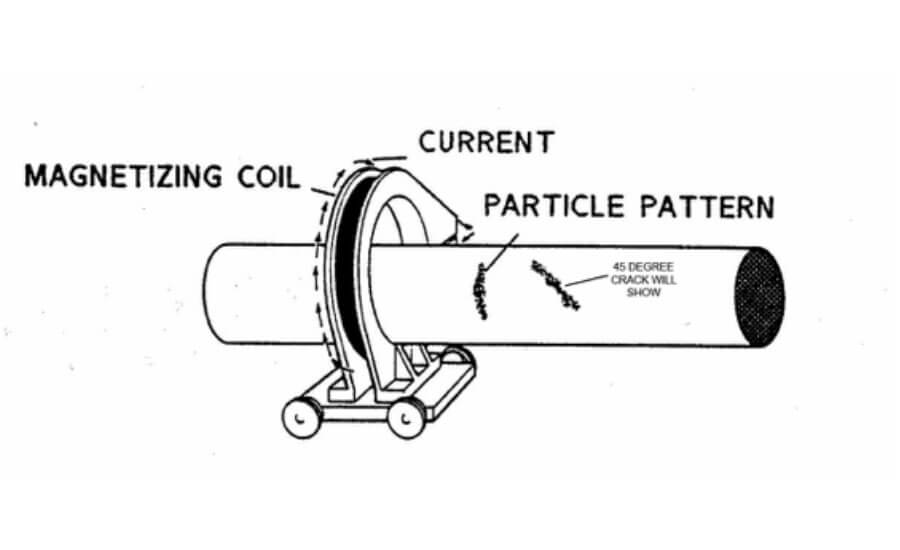

Longitudinal Fields: Longitudinal fields can be induced using coils the magnetic field is produced by current flow in a nonmagnetic coil wrapped around the test object. A yoke is also used for longitudinal magnetization of a specific portion of the test item.

Quick Fact: There is one more type of magnetization called multidirectional Magnetization. It uses several contact points and relay Switched to produce constantly varying magnetic fields and is typically used for very critical components.

Test Materials :

- Dry Particles

- Wet particles.

Wet Particles :

- A combination of smaller and large rounded particles is used.

- Are available in both oil and water base, visible / Fluorescent.

- It is Superior compared to Dry method to detect fine surface cracks.

Dry Particles :

- Particles are Larger and Heavier compared to wet particles.

- Preferable for Vertical and overhead conditions using yokes.

- It is superior to the wet method for detecting discontinuities lying wholly below the surface.

Test procedure:

- Cleaning: clean the surface to be tested, test piece surface should be free from dirt, dust, oil, flakes rust, etc.

- The magnetization of test item: Establish a suitable magnetic flux in the test object in a minimum two directions 90 degrees to the test object axis.

- Apply magnetic powder on the test piece area that is under magnetic flux. Particles can be either be in dry or wet form.

- Test the object for discontinuities under suitable lighting conditions.

- Interpretation and Evaluation of test Indications.

- Demagnetization of test pieces when necessary.

- Cleaning of the job prior to the magnetization of the Test piece can be done simply by using cotton, thinners, cleaners or sandblasting.

- Surface preparation is also required before performing the test so as per requirements in reference standard so that no false indications occur or no defects remain hidden due to the surface of the job.

- Magnetization is carried out by different types of equipment we discussed above depending on job size, geometry, possible defects, and Job criticality.

- Evaluation The fined particles get accumulated around the discontinuity which is evaluated by certified personnel.

To know how to Become certified NDT technician Read our blog: Beginners Guide To Non-Destructive Testing(NDT) – UPDATED 2020

Demagnetization:

Ferrous materials usually retain some residual magnetic field after the magnetizing current is removed.

Need For Demagnetization

- Difficulty in Post Cleaning.

- Interference in Welding due to arc Blow.

- Cause Chips to cling to the test object during Machining.

- Particles attracted can be a cause of harm in-service Conditions of Part.

- Difficulty in Magnetization of a part in Different Direction

Quick Tip: Demagnetization can be simply done by passing the object through an alternating coil that will magnetize the test object to a higher level than the Residual field.

Applications of Magnetic Particle Testing.

- Detection of Production discontinuities like seams, laps, grinding cracks and quenching cracks in ferromagnetic materials.

- Detection of In-service damage like fatigue cracks and overload cracks.

- Inspection of Welds.

- Inspection of Casting Surfaces.

Advantages:

- After Visual Testing, it is the most cost-effective, simple and fast.

- High Reliability for detection of fine Surface/Slightly Subsurface Cracks.

- Can detect discontinuities through Smeared Metals.

Limitations:

- It cannot be used for non-magnetic materials like glass, ceramics, plastics, etc.

- Needs very high Current to magnetize bigger size components.

References :

https://www.researchgate.net/figure/Principle-of-magnetic-flux-leakage_fig12_276831963/download

Brainly.in

ASNT magnetic particle testing Student Guide

Wikipedia

http://iamtechnical.com/right-hand-grip-rule

Pingback: Introduction to Eddy-current Testing(ECT) | World Of NDT

Pingback: Magnet and Principles of Magnetism | World Of NDT

I cannot thank you enough for the blog.Really thank you! Great.

Really enjoyed this article post.Thanks Again. Much obliged.

Wow, great article. Much obliged.

Pingback: Magnetization Techniques in MT | World Of NDT