what is NAS 410

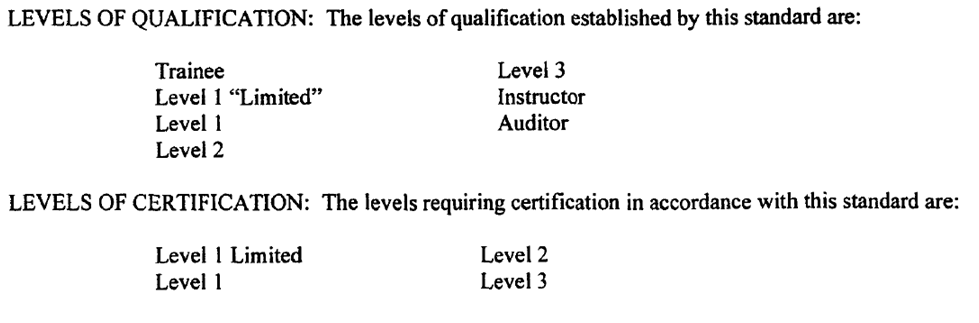

National Aerospace Standard (NAS) 410 is an industry standard published by AIA, which defines the minimum requirements for the qualification and certification of nondestructive testing (NDT) personnel. The requirements include: formal training, experience, examinations, and vision examinations. This standard establishes the minimum requirements for the qualification and certification of personnel involved in nondestructive testing (NDT). These requirements include training, experience and examinations for personnel performing NDT in the aerospace manufacturing, service, maintenance and overhaul industries.

To learn about NDT personnel qualification and certification requirements as per ASNT – Read our blog:

To learn about NDT personnel qualification and certification requirements as per PCN – Read our blog:

COMMON METHODS of certification : This standard contains detailed requirements for the applicable training, experience, and examination for the following common NDT methods:

- Liquid Penetrant (PT)

- Magnetic Particle (MT)

- Eddy Current (ET)

- Ultrasonic (UT)

- Radiography (RT)

OTHER METHODS: This standard may apply to other NDT methods that can be used to determine the acceptability or suitability for intended service of a material, part, component, sub-assembly or assembly without impairment of the intended part function. Such methods include, but are not limited to, acoustic emission, neutron radiography, penetrant leak testing, thermography, holography, and computed tomography. The requirements for personnel training, experience, and examination for these other methods shall be as established by the cognizant NDT organization or NANDTB and shall be in accordance with the guidelines established for the methods listed above.

Definitions

COGNIZANT NDT ORGANIZATION: The prime contractor or employer’s organization recognized as being responsible for administering qualification and certification of NDT personnel.

NATIONAL AEROSPACE NDT BOARD (NANDTB): An independent national aerospace organization representing a nation’s aerospace industry that is chartered by the participating prime contractors and recognized by the nation’s regulatory agencies to provide or support NDT qualification and examination services in accordance with this standard. Such services may include participation in certification.

RESPONSIBLE LEVEL 3: The responsible Level 3 or NANDTB who prepares the training and examination program shall have a thorough knowledge of the written instructions, codes, specifications and standards used by the prime contractor. He/she shall also have a thorough knowledge of the materials, components, product technologies, methods and techniques used by the employer.

TRAINING AND EXPERIENCE REQUIREMENTS :

TRAINING: Candidates for certification as Level 1 “Limited”, Level 1, or Level 2 shall complete sufficient organized training to become proficient with the principles and practices of the applicable test method and technique(s). The training shall be conducted in accordance with a detailed course outline approved by the responsible Level 3 or NANDTB.

At a minimum, the training shall cover basic theory, test principles, products, equipment operation and standardization, safety, operating procedures, applicable techniques, the applicable specifications, codes, and written instructions used by the employer, and, if applicable, interpretation of indications. The outline shall include a list of references from which the training material is derived. General, specific and practical training may be obtained with the employer or outside agency and shall always be supplemented by practical on-the-job training with the employer.

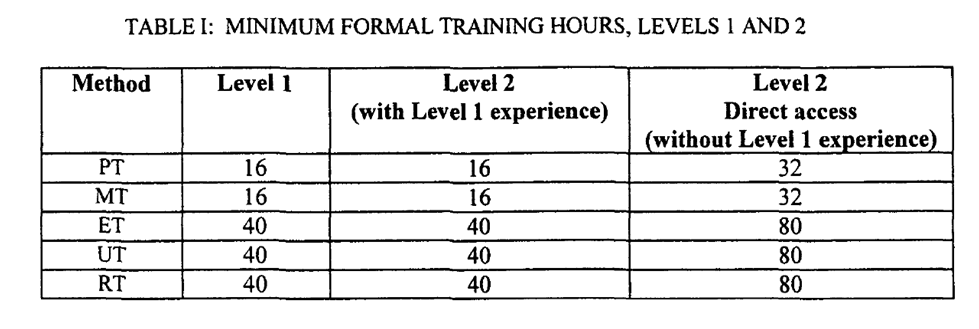

MINIMUM REQUIRED TRAINING HOURS REQUIREMENTS :

for those NDT methods not covered by Table I shall be determined by the responsible Level 3, Level 1 “Limited” hours shall not be less than 25% of those required for Level 1 in the applicable method. When determining training hours for methods not listed in Table I, the minimum hours shall be based on the requirements for a listed method of similar complexity.

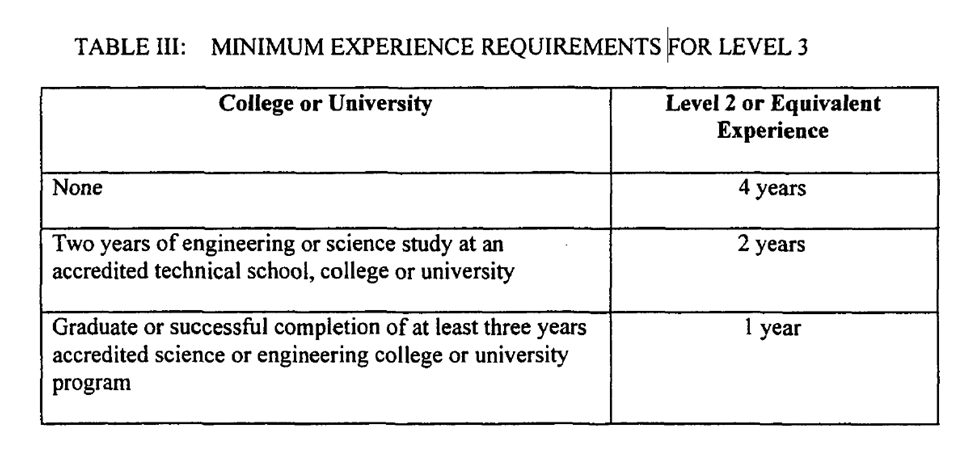

There are no additional training requirements to progress from Level 2 to Level 3 nor can an individual have sufficient training to allow certification to Level 3 without prior certification as a Level 2 or performance equivalent to a Level 2.

PREVIOUS TRAINING: Previous training must be documented to be accepted by the employer. For personnel credited with prior training, or those not certified within 12 months of their training, refresher training must be provided. At a minimum, refresher training shall cover products, equipment setup, operation and standardization, specific operating procedures, applicable techniques, interpretation and evaluation of NDT results, safety, and applicable codes, standards and specifications. The depth of instruction on each subject shall be determined by the responsible Level 3 or NANDTB.

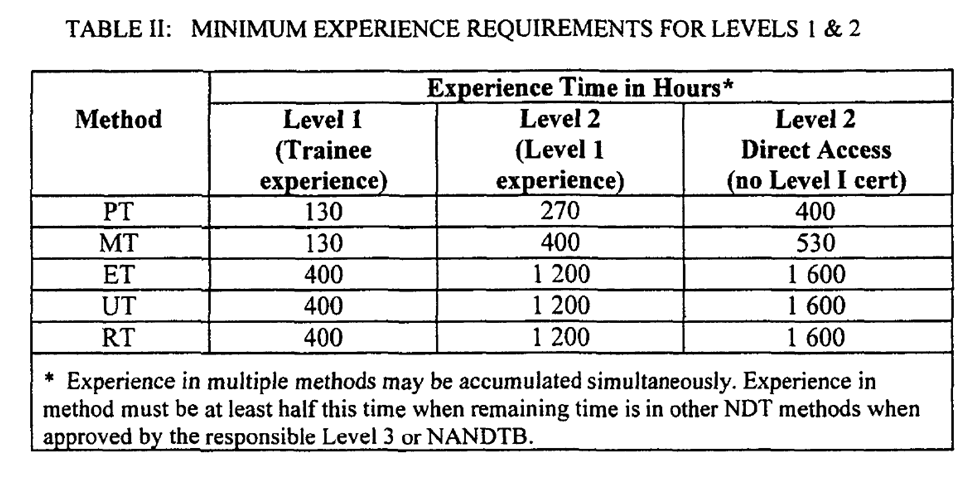

EXPERIENCE: Candidates for certification at Level 1 “Limited”, Level 1, Level 2 or Level 3 shall have sufficient practical experience to assure that they are capable of performing the duties of the level for which certification is sought. The minimum experience requirements for Levels 1 and 2 are provided in Table II, while the requirements for Level 3 are in Table III. Experience requirements for Level 1 “Limited” shall be determined by the responsible Level 3, but shall not be less than 10% of those required for Level 1 in the applicable method.

PREVIOUS EXPERIENCE: A candidate’s documented experience with a previous employer may be accepted by the current employer if approved by the responsible Level 3 or NANDTB.

EQUIVALENT EXPERIENCE: For personnel certified under other qualification programs, the equivalency of their previous experience to the requirements of Tables II or III will be determined and documented by the responsible Level 3 or NANDTB.

EXAMINATIONS REQUIREMENTS

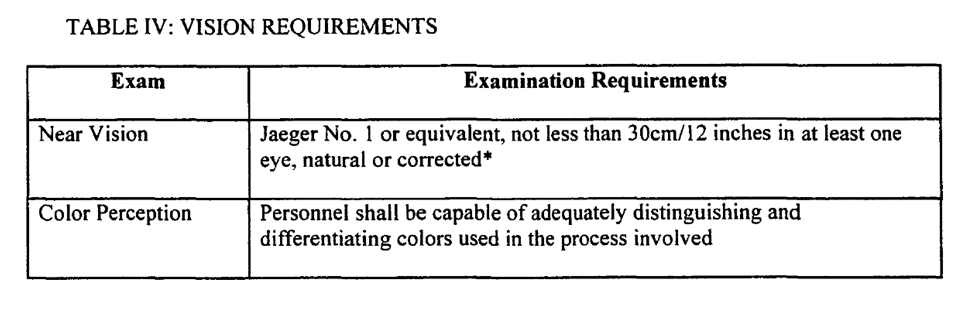

VISUAL ACUITY: The vision examination for all levels shall assure that the applicants near vision and color perception meet the requirements of Table IV. Near vision tests shall be administered annually and color perception tests shall be administered prior to certification or re-certification. These tests shall be administered by personnel designated by the responsible Level 3, NANDTB, or the outside agency utilized for the qualification examination of personnel. Any limitations in color perception shall be evaluated by the responsible Level 3 prior to certification and must be approved in writing.

GENERAL: The general examination for all levels shall be a closed book examination consisting of questions that cover the cross-section of the applicable method at the appropriate level. The responsible Level 3 shall determine the general examination requirements for Level 1 “Limited” personnel, but shall not be less than 25% of those required for Level 1 in the applicable method.

A minimum of 40 questions shall be used for the general examination at Levels 1, 2 or 3. For the Level 3, the general examination questions will address the general knowledge of other methods used by the employer as well as the method for which certification is sought. Possession of a current ASNT NDT, EN 473 or IS0 9712 Level 3 certificate by the candidate may be satisfactory evidence that the general examination requirement is satisfied as defined in the employer’s written practice.

SPECIFIC: The specific examination for all levels shall be a closed book examination and shall cover the requirements and use of the specifications, codes, equipment, operating procedures, and test techniques the candidate may use in the performance of his/her duties with the employer. The responsible Level 3 shall determine the specific examination requirements for Level 1 “Limited” personnel, but shall not be less than 25% of those required for Level I in the applicable method.

A minimum of 30 questions shall be used for the specific examination at Levels 1,2, and 3. Reference material such as specifications, tables, formulas, etc. may be provided as determined by the responsible Level 3. Questions utilizing such material shall require understanding of the information contained therein rather than merely finding its location.

NOTE: Where a NANDTB is used, the specific examination may cover a wider scope within the method used within the aerospace industry.

PRACTICAL: The practical examination shall consist of a demonstration of proficiency in performing tasks that are typical of those to be accomplished in the performance of the candidate’s duties. Test samples used in the examination may be actual hardware if the candidate is required to demonstrate proficiency in the application of the process as well as interpretation of results, or may be images, such as radiographs if the candidate is only required to interpret the results and not perform the process of generating the image.

Written checklists covering the topics detailed in the following sub-paragraphs shall be developed by the responsible Level 3 or NANDTB to assure adequate coverage and to assist in the administration and grading of the examination.

NOTE: Where a NANDTB is used, the practical examination may cover a wider scope within the method used within the aerospace industry.

GRADING: The candidate for certification must achieve a minimum grade of 70% on the general and specific examinations. The candidate must detect ail discontinuities or conditions specified by the Level 3 during the practical examination and achieve a minimum score of 70%. The candidate must have an average score of no less than 80% in order to be eligible for certification. All examination scores shall be of equal weight in determining the average score. Scores for third party examinations where grading is a “pass/fail”, the value of “pass” used for the average score shall be 80%.

References:

- https://www.nas410.com/#:~:text=National%20Aerospace%20Standard%20410%20is,%2C%20examinations%2C%20and%20vision%20examinations.

- NAS 410

- Feature image by Photo by Call Me Fred on Unsplash