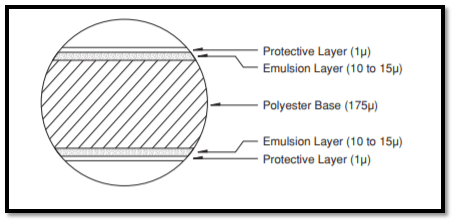

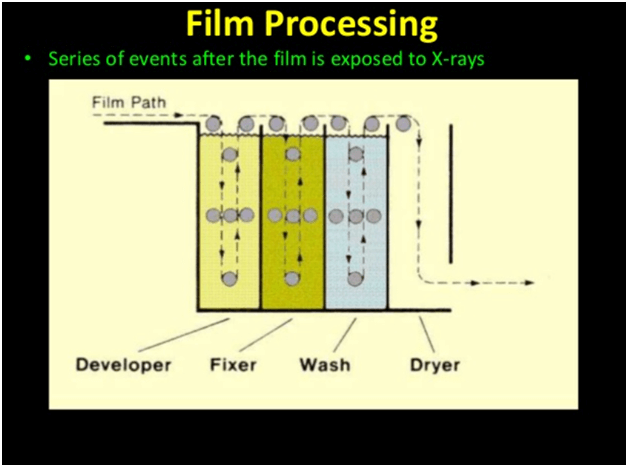

Radiographic Film processing refers to a series of steps to convert the latent image (invisible) on the film into a visible image. X-ray films for industrial radiography consist of an emulsion and a blue-tinted base of polyester 175μ thick. The emulsion is coated on both sides of the base in layers and protected on both sides with thin outer protective layers. The emulsion consists of silver halides as the photosensitive material, additives, and gelatin. The silver halides form an image when influenced by X-rays, gamma rays, secondary electrons, or fluorescent light. To produce a satisfactory radiograph, the care used in making the exposure must be followed by equal care in processing. The most careful radiographic techniques can be nullified by incorrect or improper darkroom procedures.

Credits : Slideshare X ray film & film processing by Rakesh Ca

To learn more about Radiography testing read our blog :

Introduction to Radiographic Testing(RT).

Film processing, whether it is manual or automatic, comprises five basic steps:

- developing,

- rinsing or stop bath,

- fixing,

- washing, and

- drying.

Credits : SlideShare X ray film & film processing by Rakesh Ca

Developer

When photographic film is exposed to light or radioactive rays, an invisible image (called a latent image) is formed in the emulsion layer of the film. The process of converting the latent image to a visible image is called development, and a developer solution is used in this process.

Developing Agent -Monol (equivalent of Metol), hydroquinone, Pyrazon (equivalent of Phenidone), etc.

Other Ingredients

- Accelerator -Sodium carbonate, sodium hydroxide, etc.

- Preservative – Sodium sulfite, sodium bisulfite, etc.

- Restrainer – Potassium bromide, etc.

- Additives – Gelatin hardener, water softener, etc.

Stop Bath

The silver image becomes too dense to serve the intended purpose unless the action of the developer is stopped at a proper time. If the film is directly transferred from the developer into the fixer, uneven fixation is liable to occur. To stop the action of the developer and prevent uneven fixation, a 1.5 to 3% solution of acetic acid is used as the stop bath. In radiography, a 3% solution of acetic acid is used. If the stop bath is not used, the developer carried over with the film not only increases the exhaustion of the fixer but may become the cause of a lack of processing uniformity or stain formation in the radiograph

Fixer

After development and stop bath neutralization the emulsion still contains unreduced silver halide which is not necessary for the image. Such material is detrimental, especially to the radiograph as viewed by transmitted light. The fixer is used to remove the unreduced silver halide.

The commonest fixing baths are solutions of sodium thiosulfate. Ammonium thiosulfate is also used when quick fixation is required. These chemicals possess activity that converts silver halides to soluble compounds. The emulsion which is softened by the developer is hardened by the fixer. Acid hardening baths that stop the action of the developer carried with the film and harden the emulsion are used in all fields of photography, let alone radiography. Almost all fixers in common use are of this acid hardening type. The fixer contains a solvent for silver halide and other ingredients, as shown below.

Fixer-Silver Halide Solvent-[Sodium and ammonium thiosulfates]

Other Ingredients

- Preservative -[Sodium sulfite, etc.]

- Acid -[Acetic acid, etc.]

- Hardener -[Potassium alum, etc.]

- Buffer -[Nabox] (equivalent to Kodalk mild alkali), etc.]

Wetting Agent

When the washed film is dried the processing is completed. After the wash step, water adheres to the film in streaks and drops. If the film is dried in this condition, not only will the drying time be extended but watermarks will be left on the radiograph. To reduce drying time and prevent watermarks, a wetting agent is used.

Manual Processing

- Preparation—No more film should be processed than can be accommodated with a minimum separation of 1⁄2 in. (12.7 mm). Hangers are loaded and solutions stirred before starting development.

- Start of Development—Start the timer and place the films into the developer tank. Separate to a minimum distance of 1⁄2 in. (12.7 mm) and agitate in two directions for about 15s.

- Development—Normal development is 5 to 8 min at 68°F (20°C). Longer development time generally yields faster film speed and slightly more contrast. The manufacturer’s recommendation should be followed in choosing a development time. When the temperature is higher or lower, development time must be changed. Again, consult manufacturer-recommended development time versus temperature charts.

- Agitation—Shake the film horizontally and vertically, ideally for a few seconds each minute during development. This will help the film develop evenly.

- Stop Bath or Rinse—After development is complete, the activity of the developer remaining in the emulsion should be neutralized by an acid stop bath or, if this is not possible, by rinsing with vigorous agitation in clear water. Follow the film manufacturer’s recommendation of stop bath composition (or length of alternative rinse), time immersed, and life of the bath.

- Fixing—The films must not touch one another in the fixer. Agitate the hangers vertically for about 10 s and again at the end of the first minute, to ensure uniform and rapid fixation. Keep them in the fixer until fixation is complete (that is, at least twice the clearing time), but not more than 15 min in the relatively fresh fixer. Frequent agitation will shorten the time of fixation.

- Fixer Neutralizing—The use of a hypo eliminator or fixer neutralizer between fixation and washing may be advantageous. These materials permit a reduction of both time and amount of water necessary for adequate washing. The recommendations of the manufacturers as to the preparation, use, and useful life of the baths should be observed rigorously.

- Washing—The washing efficiency is a function of wash water, its temperature, and flow, and the film being washed. Generally, washing is very slow below 60°F (16°C). When washing at temperatures above 85°F (30°C), care should be exercised not to leave films in the water too long. The films should be washed in batches without contamination from the new film brought over from the fixer. If pressed for capacity, as more films are put in the wash, partially washed film should be moved in the direction of the inlet. The cascade method of washing uses less water and gives better washing for the same length of time. Divide the wash tank into two sections (maybe two tanks). Put the films from the fixer in the outlet section. After partial washing, move the batch of film to the inlet section. This completes the wash in freshwater.

- Wetting Agent—Dip the film for approximately 30 s in a wetting agent. This makes water drain evenly off film which facilitates quick, even drying.

- Residual Fixer Concentrations— If the fixing chemicals are not removed adequately from the film, they will in time cause staining or fading of the developed image. Residual fixer concentrations permissible depend upon whether the films are to be kept for commercial purposes (3 to 10 years) or must be of archival quality. Archival quality processing is desirable for all radiographs whenever average relative humidity and temperature are likely to be excessive, as is the case in tropical and subtropical climates. The method of determining residual fixer concentrations may be ascertained by reference to ANSI PH4.8, PH1.28, and PH1.41.

Note: Film and chemical manufacturers should be consulted for detailed recommendations on manual film processing. This section outlines the steps for one acceptable method of manual processing. Other recommendations of the manufacturer to be followed are replenishment rates, renewal of solutions, and other specific instructions.

Drying

Drying is a function of

- film (base and emulsion);

- processing (hardness of emulsion after washing, use of wetting agent); and

- drying air (temperature, humidity, flow).

Manual drying can vary from still air drying at ambient temperature to as high as 140°F (60°C) with air circulated by a fan. Film manufacturers should again be contacted for recommended drying conditions. Take precaution to tighten film on hangers, so that it cannot touch in the dryer. Too hot a drying temperature at low humidity can result in uneven drying and should be avoided.

References:

- https://www.fujifilm.com/products/ndt/pdf/ix-film_fundamentals_of_industrial_radiography.pdf

- ASME BPVC Sec – V, SE-94

- slideshare.net