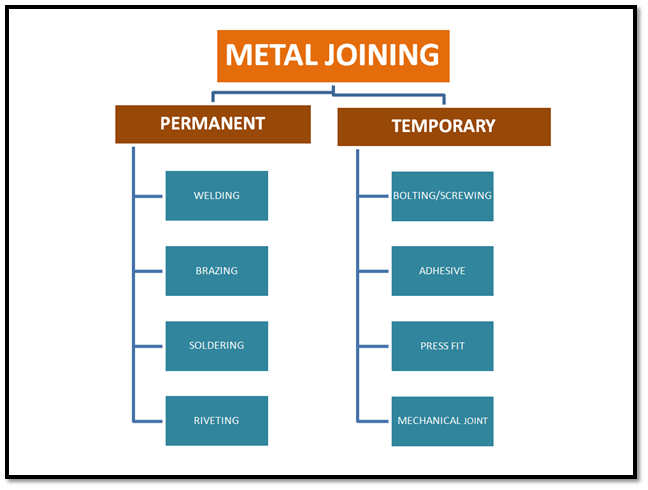

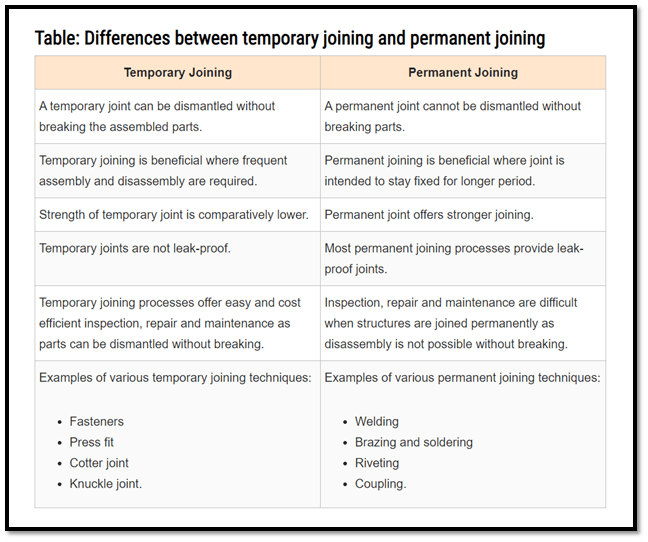

Metal Joining Technology is defined as joining of two metal parts either temporarily or permanently with or without the application of heat or pressure. it offers multiple benefits compared to other manufacturing processes such as No thermal structural transformation of workpieces, Numerous choice of material of rivets, sizes, forms, etc. High strength capacity, mobility of material after joining, Easy to control quality, Good environmental behavior – no emission or pollution. in this article, we will have a brief of different metal joining processes.

To learn more about casting process and engineering materials read our blogs

Permanent Metal Joining:

a permanent joint is one that does not allow disassembly of joined components without rupturing them. Welding, riveting, coupling, etc. are common examples of such a process. It can provide a sound, reliable, leak-proof, and sufficiently strong joint and thus can be safely used for heavy load applications.

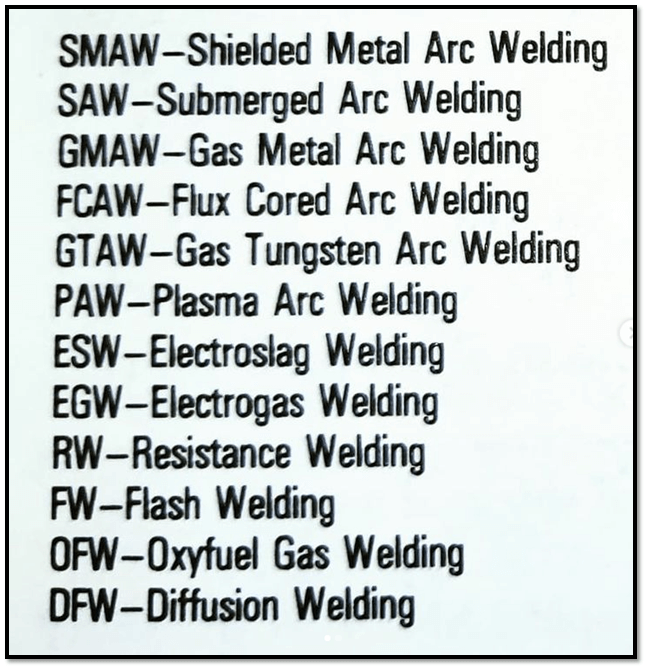

Welding process:

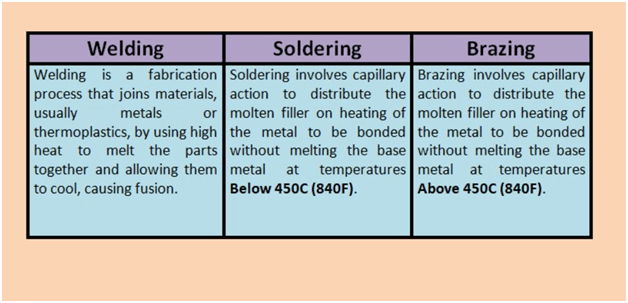

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material (parent metal). Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized.

Brazing

It’s a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the workpieces and from soldering in using higher temperatures for a similar process, while also requiring much more closely fitted parts than when soldering. The filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting (liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the workpieces together. A major advantage of brazing is the ability to join the same or different metals with considerable strength.

Soldering

is a process in which two or more items are joined together by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the workpieces. In brazing, the workpiece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated the use of lead-free alloys for electronics and plumbing

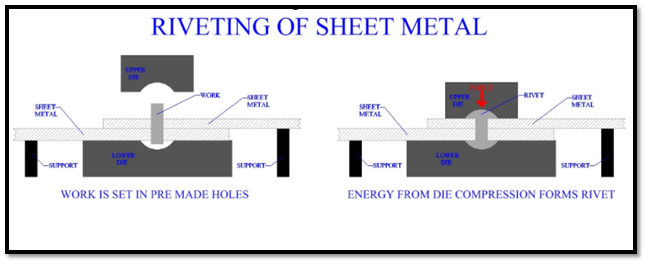

Riveting

is a forging process that may be used to join parts together by way of a metal part called a rivet. The rivet acts to join the parts through adjacent surfaces. A straight metal piece is connected through the parts. Then both ends are formed over the connection, joining the parts securely. The metal workpiece used to form the connection may be hollow or it may be solid. Rivets have many uses, such as in the construction and sheet metal industries.

Credits: https://thelibraryofmanufacturing.com/riveting.html

Temporary joining

These processes are all those joining processes that allow easy dismantling of joined components without rupturing them. It facilitates assembly and disassembly of solid structures as and when required without harming them.

Bolting

In this metal joining process, the metallic parts are joined together by means of Bolt/screw and nuts. This process is widely used in the assembly of the part to be joined temporarily or joints that require periodic maintenance. A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevent pull-out.

Press-fit

Also known as a force fit or interference fit, a press fit is an assembly in which one part is inserted tightly into a hole in another part. The inserted part is typically 0.001 to 0.002 inches larger than the mating hole. In engineering terms, a press-fit— also known as an interference fit— is the fastening of two parts that is achieved by normal force, friction, and cold welding. This happens when a shaft is inserted tightly into a slightly smaller hole in another part, with the interference holding both parts in place.

Mechanical joints

A mechanical joint is a section of a machine which is used to connect one or more mechanical part to another. Joints are found in all types of machines, produces, and workpieces. When two or more surfaces are joined together, they form a joint. Mechanical joints may be temporary or permanent, most types are designed to be disassembled. Mechanical joints typically allow a limited range of movement, which is essential to their operation. Most mechanical joints are designed to allow relative movement of these mechanical parts of the machine in one degree of freedom and restrict movement in one or more others.

Types of mechanical joints.

- Pin joint

- Prismatic joint

- Ball joint

- Knuckle joint

- Turnbuckle

- Cotter joint

- Bolted joint

- Screw joint

- Universal joint

Adhesive bonding

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such as mechanical fasting by the use of nails, rivets, screws or bolts, and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.

Some of these benefits include:

- Ability of the adhesive to distribute loads evenly throughout the bond line while mechanical fasteners generate areas of higher stress concentration.

- Eliminates the costly operation of drilling or punching holes in members to be connected.

- Reduction in weight and better aesthetics

The different types of structural adhesives are:

- Epoxies

- Toughened acrylics

- Polyurethanes

- Cyanoacrylates

- Anaerobics

- Phenolics

- Vinyl acetates

References

- Wikipedia

- Slideshare

- Feature image: Photo by Leo Fosdal on Unsplash

I couldn’t agree more! This post is a true gem for knowledge seekers.