Exposure time calculation in RT

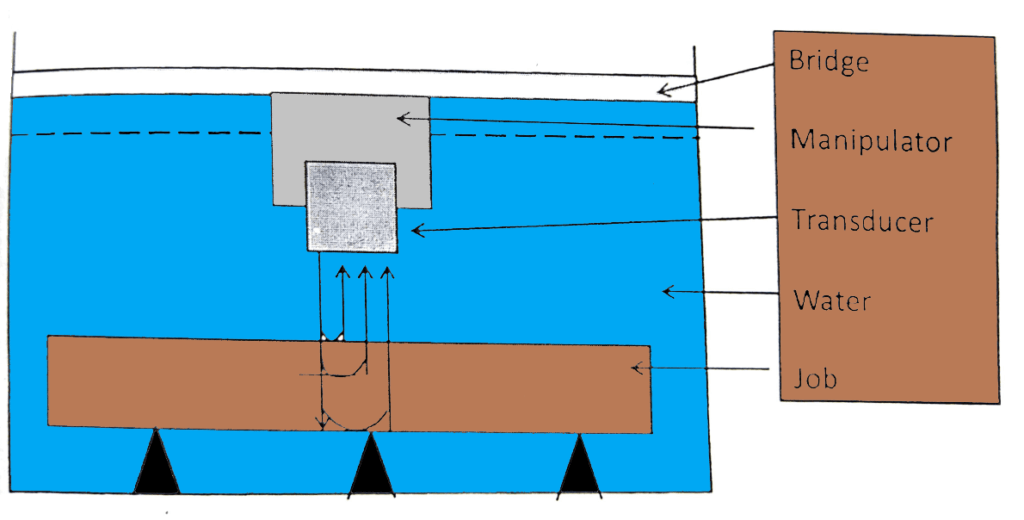

Exposure time calculation in RT is very important to perform radiography tests and develop radiographs meeting the standard requirements. Exposure time is the time required for sufficient radiation energy to ionize […]

Exposure time calculation in RT Read More »