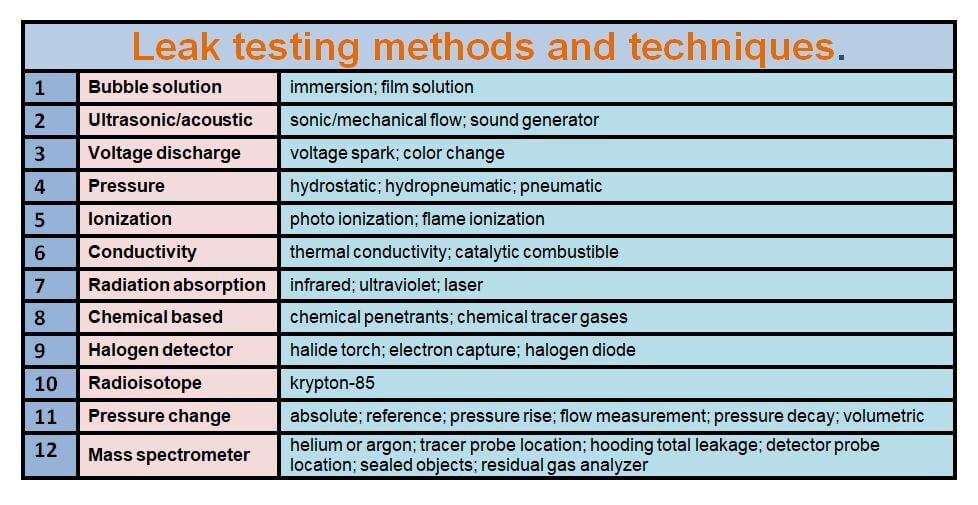

Leak testing is a form of nondestructive testing used in either pressurized or evacuated systems and components for detection and location of leaks and for measurement of fluid leakage. leak testing comprises procedures for detecting or locating or measuring leakage, or combinations thereof. In this article, we will have an introduction to leak testing and Helium leak testing.

Important Definitions

- leak: a hole, or void in the wall of an enclosure, capable of passing liquid or gas from one side of the wall to the other under the action of pressure or concentration differential existing across the wall, independent of the quantity of fluid flowing. A leak may be a crack, crevice, fissure, hole, or passageway.

- leakage: the fluid, either liquid or gas, flowing through a leak and expressed in units of mass flow; i.e., pressure and volume per time.

- leakage rate: the flow rate of a liquid or gas through a leak at a given temperature as a result of a specified pressure difference across the leak. Standard conditions for gases are 25°C and 100 kPa. Leakage rates are expressed in various units such as pascal cubic meters per second or pascal liters per second.

- leak standard (standard leak): a device that permits a tracer gas to be introduced into a leak detector or leak testing system at a known rate to facilitate calibration of the leak detector.

- A leak detector’s sensitivity is a measure of the concentration or flow rate of tracer gas that gives a minimum measurable leak signal. Sensitivity depends on the minimum detectable number of tracer gas molecules entering the detector. The sensitivity of a leak detector is independent of the pressure in the system being tested, provided that time is ignored as a test factor.

- Leak test sensitivity refers to the minimum detectable amount of leakage that will occur in a specific period of time under specified leak test conditions. It is necessary to state both the leakage rate and the prevailing test conditions to properly define leak test sensitivity in terms of the smallest physical size leak that can be detected.

Reasons for Leak Testing

The purposes of leak testing are to ensure reliability and serviceability of components and to prevent premature failure of systems containing fluids under pressure or vacuum.

Leaks are special types of anomalies that can have tremendous importance where they influence the safety or performance of engineered systems. The operational reliability of many devices is greatly reduced if enough leakage exists.

Leak testing is performed for three basic reasons:

- to prevent material leakage loss that interferes with system operation;

- to prevent fire, explosion, and environmental contamination hazards or nuisances caused by accidental leakage;

- to detect unreliable components and those whose leakage rates exceed acceptance standards.

Leak testing can be divided into three main categories:

- leak detection,

- leak location and

- leakage measurement.

Types of Fluid Media Used in Leak Testing

Each technique in all categories involves a fluid leak tracer and some means for establishing a pressure differential or other means for causing fluid flow through the leak or leaks. Possible fluid media include gases, vapors, and liquids or combinations of these physical states of fluid probing media. Gases and vapors are generally preferred to liquid media where high sensitivity to leakage must be attained; however, liquid probing media are used for leak testing in many specific applications.

Selection of the desired fluid probing medium for leak testing depends on operator or engineering judgment involving factors such as:

(1) type and size of test object or system to be tested;

(2) typical operating conditions of test object or system;

(3) environmental conditions during leak testing;

(4) hazards associated with the probing medium and the pressure conditions involved in testing;

(5) leak testing instrumentation to be used and its response to the probing medium;

(6) the leakage rates that must be detected and the accuracy with which measurements must be made; and

(7) compatibility of test probing medium with test object and content (to avoid corrosion etc.).

Factors Influencing Choice between Detector Probe and Tracer Probe Tests

One of the most difficult and important decisions is the choice of which leak testing method should be used. A correct choice will optimize sensitivity, cost and reliability of the leak testing procedure. Choice of an incorrect test method makes leak testing less sensitive and less reliable, while adding to the difficulty of testing.

One simplified way to choose is to rank various leak testing methods by means of their leakage sensitivity. If this were sufficient, the test engineer would only need to decide what degree of sensitivity is required and then to select the test method from among those offering adequate sensitivity for the specific test application.

However, each leak testing technique can have different test sensitivity under different operating conditions. For example, a mass spectrometer leak detector is 10 000 times more sensitive than a heated anode halogen vapor detection instrument when used for leak location in the tracer probe leak location test of an evacuated vessel. However, if these two instruments are used for leak detection on a pressurized test system, the halogen leak detector is 100 times more sensitive. The reason for this apparent discrepancy becomes obvious on close examination of the operating characteristics of these two instruments. The mass spectrometer is designed for operation under vacuum conditions, whereas the halogen leak detector is designed for operation in air at atmospheric pressure.

Standard Conditions for Leak Testing

The set of conditions most commonly accepted as standard for pressure measurement is that of dry air at 25 °C (77 °F), for a pressure differential between one standard atmosphere and a vacuum (a standard atmosphere is roughly 100 kPa or precisely 101.325 kPa).

For practical purposes, the vacuum need be no better than 0.01 of an atmosphere or 1 kPa (0.15lbf·in.–2). When a leak is being described and only the leakage rate is given, it is assumed that the leakage rate refers to leakage at standard conditions. The sensitivity of a leak testing instrument is synonymous with the minimum detectable leakage or minimum flow rate the instrument can detect. These minima are independent of leak testing conditions. When the instrument is applied to a test, the leak testing sensitivity depends on existing conditions of pressure differential, temperature and fluid type in addition to the instrument sensitivity. However, the leak test instrument should be more sensitive by at least a factor of 2 than the minimum leakage to be detected, to ensure reliability and reproducibility of measurements.

Helium Leak test

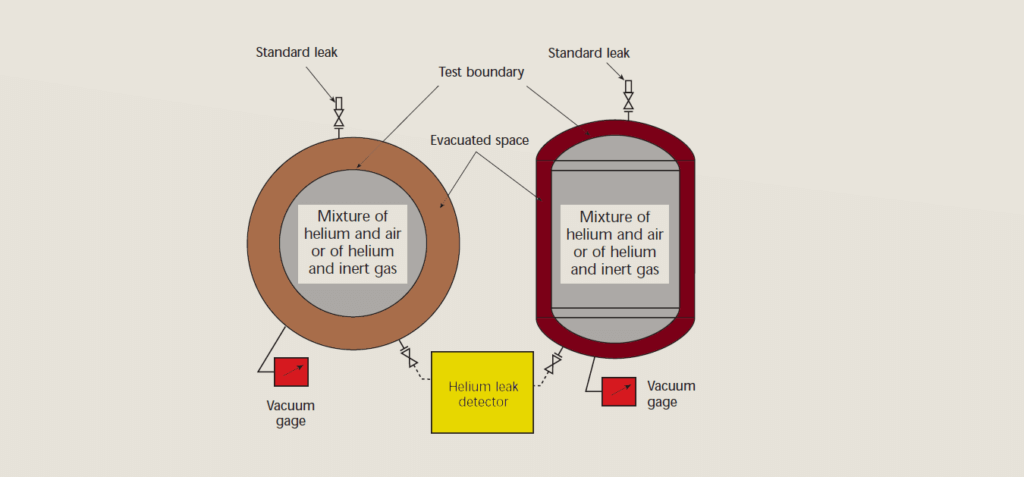

In leak testing a pressure difference between the outer and the inner side of the object to be examined is produced. Subsequently, the amount of gas or liquid which is passing through a leak is measured. In the helium leak test helium is used as a search gas, from this the nomination of the method.

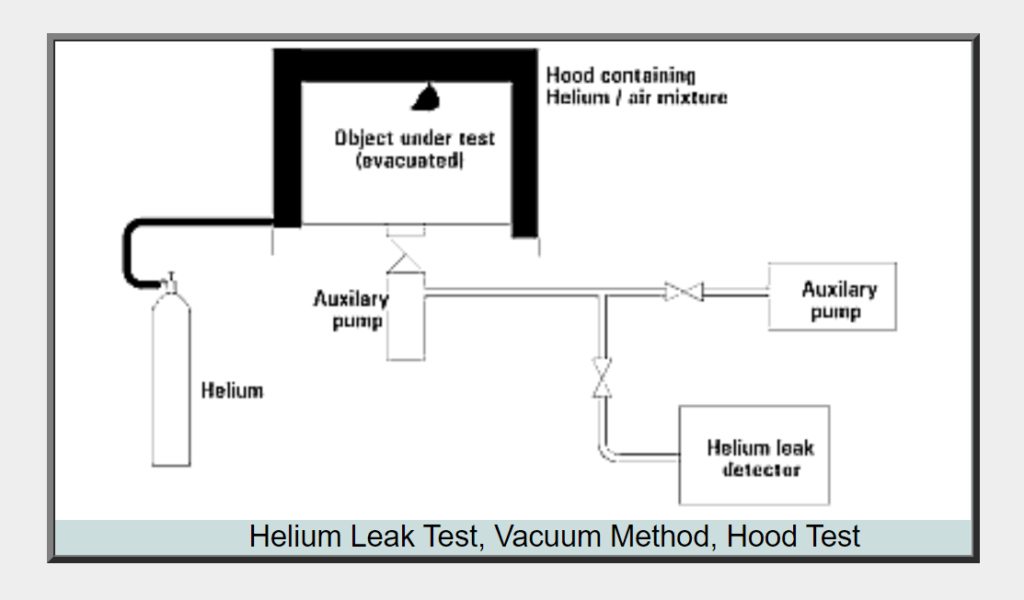

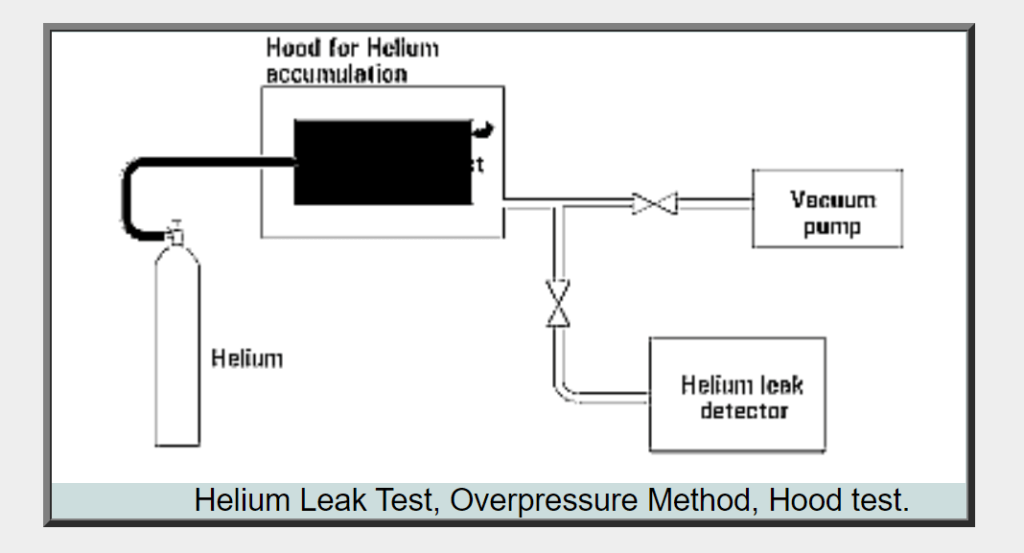

In principle, two methods are applied for leak testing and localization of leaks, the “Vacuum method” and the “Overpressure method”.

At the “Vacuum method,” the object to be examined for leaks is evacuated and sprayed from the outside with a search gas, in this case, Helium. The gas enters through any leaks present in the object and is detected by a sensor connected to the leak test instrument.

At the “Overpressure method,” the object to be examined for leaks is filled with a search gas, Helium, under slight overpressure. The search gas escapes through any leaks present to the outside and is detected by a detector probe. This detector probe is in most cases called a “sniffer” acting as a gas sampling probe.

NDT TIP – The object under test should, if possible, be tested according to its final mode of use, i.e. if it is used under vacuum, the vacuum method should be applied, if it is finally pressurized, the overpressure method should be adopted.

Vacuum method – Hood test

The Hood Test is an overall leak test. The evacuated test object is covered with a (plastic) hood. The space between the test object and the hood is filled with Helium from the search gas reservoir so the total outer surface of the test object is exposed to the Helium search gas. The helium enters through all leaks present at the evacuated test object and thus the detector connected to it. The detector now indicates the total leak rate.

The hood test can for example be used for examination of small vessels.

Overpressure method – Hood test

As in the vacuum hood test the overpressure hood test is an overall leak test. A test set-up similar to the vacuum test is used. A vacuum chamber is used for the hood, which can be evacuated by a auxiliary pump and to which the leak detector is connected. The helium search gas which is escaping through leaks in the test object is indicated by the leak detector.

The use of a helium leak detector allows detection of extremely small leaks and is suitable for automatic leak detection in industrial equipment.

The hood test can for example be used for examination of vessels, heat exchangers etc..

Some of the capabilities of the Helium Leak Test are.

- leak rates down to 10-10 mbar l / s can be detected

- both objects with vacuum or overpressure can be examined

- the objects can be examined during operation

- the examination can be performed fast and effective

- non poisonous, non explosive and inexpensive gasses are applied

- leaks can be detected in due time to prevent safety or operational hazards

- leaks can be detected in due time to prevent unplanned and expensive shut downs

Some Area’s of application of helium leak testing

• A/C Hoses

• Heat Exchangers

• Condensers

• Evaporators

• Fuel Tanks

• Diesel Pumps

• Aluminum wheel rims

• SF6 isolated switchgear

• Vacuum Tubes

• Evaporators

• Condensers

• Hermetic compressors

• Instrumentation

• Drums

• Fire Extinguishers

References :

- ASME BPVC Sec V

- NDT Handbook Leak Testing Vol. 1

- NDT.net – Industrial applications of Helium Leak Test

To learn about History of NDT Read our Blog: HISTORY OF NON-DESTRUCTIVE TESTING(NDT)

To learn about Need of NDT Read our Blog: NEED FOR NON-DESTRUCTIVE TESTING(NDT)

To learn how to begin your NDT journey Read our Blog: BEGINNERS GUIDE TO NON-DESTRUCTIVE TESTING (NDT) – UPDATED 2020

I respect you compiling these points. I am not amazed a product like this

exists in the absolutely free marketplace. I’m

amazed that it has seemingly changed the spare tire Commonly provided by the car’s producer in specific

models of new cars and trucks.